The hybrid network is the future of freight

The emergence of autonomous trucks in the freight market is no longer a matter of if, but when and how. After years of technological advances and a marked shift in mindset from the industry and the public, autonomous trucks are set to drastically affect the logistics landscape for shippers and carriers, unlocking much-needed capacity and providing new opportunities for business growth.

The growth of autonomous solutions is happening at a tipping point for freight logistics. The pandemic upended logistics operations, jump-starting a period of supply chain volatility that the industry had never before experienced. The limitations of legacy systems and existing network approaches were laid bare; shippers found themselves unable to flex with the market.

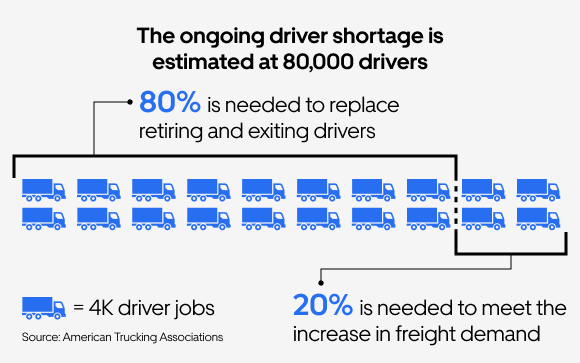

Demand that spiked abruptly during the early days of the pandemic exacerbated the existing imbalances with supply. But in reality, the freight industry has been growing at an unsustainable pace for years, with demand outpacing driver supply—a problem projected to get increasingly worse. According to the Bureau of Transportation Statistics, US freight activity is set to double in value, to more than $36 trillion, and grow 50% in tonnage, to over 28 billion tons, between 2020 and 2050.

Meanwhile, according to the American Trucking Associations, the ongoing driver shortage (especially prevalent for long-distance hauls) will require the industry to recruit heavily over the next decade to replace retiring drivers. Despite recently lowering the entry age of truck drivers to 18 in some areas, a looming cliff of thousands of truck driver retirements over the next decade is a major challenge.

It’s clear that everyone in the supply chain needs better options to keep goods moving and evolve their business operations in 2022 and beyond. This industry urgency is converging with important advancements in autonomous trucks and marketplace technologies, providing us with a preview of what’s ahead. Uber Freight, for example, launched an industry-first, strategic partnership with Waymothat unlocks billions of autonomous miles on its network for the years to come. Additionally, Uber Freight is currently running a multiphase pilot program with Aurora where Uber Freight is also learning how to integrate the Aurora Driver into its digital freight network.

But the emergence of autonomous trucks and robust digital solutions doesn’t mean that human drivers will be replaced. Instead, it’s a new era in how we approach freight: a hybrid network where autonomous trucks and human-driven trucks operate side by side to counter the growing supply and demand imbalances and the looming retirements and other driver exits—all while creating efficiency and increasing sustainability.

The hybrid network: why it’s necessary and what it looks like

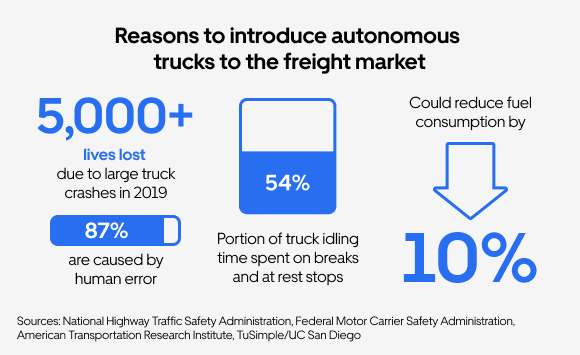

Autonomous trucks can help the industry tackle challenges that have always plagued it: improving the safety of our roads, limiting freight’s environmental footprint, and massively increasing utilization of trucking assets.

Because autonomous trucks don’t deal with fatigue or other conditions that may lead to distraction, they decrease the chance of accidents caused by human error. The National Highway Traffic Safety Administration (NHTSA) reported that in 2019, large truck crashes accounted for more than 5,000 lives lost—and 87% of large truck crashes are caused by human error, according to historical data from the Federal Motor Carrier Safety Administration (FMCSA).

Autonomous trucks are also a solution to high idle times, empty miles, and trucking’s environmental impact. Autonomous trucks can contribute to more environmentally friendly business practices. Since they don’t idle at truck stops and rest stops (which accounts for 54% of truck idling time, according to the American Transportation Research Institute) during long hauls that require human drivers to stop, they can reduce unnecessary emissions. Autonomous trucks can also travel during off-peak hours and use braking more efficiently than human drivers, saving on fuel expenses and reducing carbon emissions. A 2019 TuSimple/UC San Diego study found that driverless trucks could reduce fuel consumption by at least 10%.

Despite the many benefits of autonomous truck adoption, the role of human drivers remains crucial. Autonomous trucks are designed to handle extensive highway journeys, which will accommodate the industry’s growing need for more long-haul drivers, but human drivers will always be needed for the more intricate responsibilities of freight transportation: things like short hauls, hauling certain types of loads, driving in poor weather conditions, inspections, paperwork, and scheduling.

The hybrid network will support the collaboration of human-driven trucks and autonomous trucks, elevating the work of today’s truck drivers while presenting a new way for carriers to scale their businesses by investing in autonomous trucks. If built and deployed properly, the hybrid network will provide shippers with access to both types of trucks within the same marketplace and, in turn, increase the capacity of trucks necessary to adapt to the growing demand. Having both options available in a single network offers a quick and innovative way to give shippers capacity, when and where they need it.

How technology is pushing the hybrid network forward

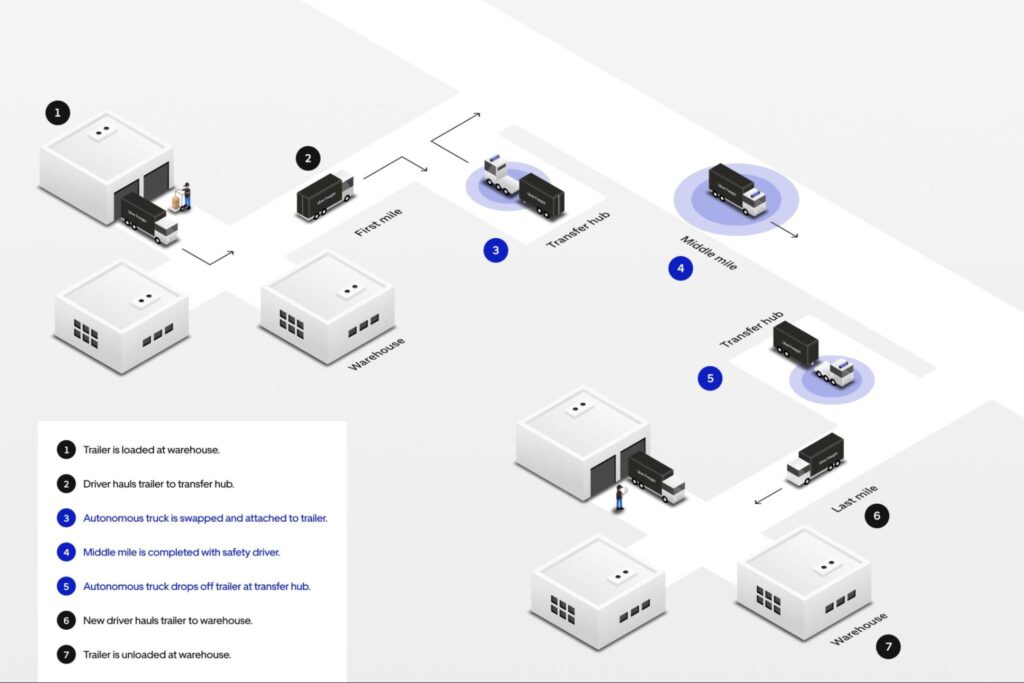

In 2022, pilot programs facilitated by Uber Freight in the Southwest have been testing how the hybrid network can perform through a hub-to-hub model. These pilots are built on top of Uber Freight’s existing universal trailer pool program, Powerloop. The model functions by having humans handle the first leg of freight transport, autonomous trucks (with safety drivers) handle the middle leg, and humans take over the final leg.

Here’s a breakdown: A human driver picks up a preloaded trailer from a shipper facility and takes it to a transfer hub that’s located near a highway. That trailer will then get hooked to an autonomous truck, which drives the freight on a highway to a second transfer hub near the receiver’s facility. A human driver will then pick up the trailer at that second hub and deliver it to the final destination.

At its core, the hub-to-hub model allows for humans to handle the more complex tasks that autonomous trucks can’t, such as navigating urban streets, loading and unloading, going through security checks at gate entrances, and completing freight documentation. By tackling the more grueling long-haul portion of driving, autonomous trucks can ease some of the burden of the increasing demand for freight while enabling drivers to shift into short-haul jobs that get them home more often.

The hub-to-hub model, running within Uber Freight’s marketplace, uses technology as its anchor: leveraging algorithms to match shippers with the right trucks based on factors such as the type of freight they need to move and when they need to move it. This approach means that loads will always automatically be matched with compatible autonomous trucks as well as carriers to handle human-driven legs of a trip—all while ensuring that trips are completed seamlessly through back-end operational support.

Uber Freight is committed to scaling the strategy of connecting autonomous trucks and human-driven trucks. The hub-to-hub model is just the beginning. Scaling this approach will not only solve the challenges the freight industry faces today, but also create opportunities for the future.